Product Description

Air Cooled Fiber Laser Welding Machine This product has high integration, small size, light weight and easy operation. Equipped with a welding head of only 0.8kg, the laser beam is highly concentrated and the power output is stable. And with the advantages of air cooling, high photoelectric conversion efficiency, low power consumption, energy saving, economic and practical, beautiful weld, no deformation, no deformation of weldparts, no follow-up treatment, not affected by the working environment temperature, cold and hot weather can work normally, stable continuous work for 72 hours, the machine preset common welding parameters, At the same time, users can customize and save the required processing parameters.

Machine Advantage

1. Not affected by the working environment temperature (-20 degrees -+40 degrees),

it can work normally in cold and hot summer, and work steadily for 72 hours.

2. The laser beam is highly concentrated and the power output is stable, which can

easily weld high inverse materials.

3. High photoelectric conversion efficiency, low power consumption, energy saving,

economic and practical.

4. It can be matched with a mechanical arm to achieve a variety of flexible applications.

5. High integration, small size, light weight,saving shipping fee and occupied area.

Laser Source

Professional welding laser source, small in size, light in weight, and easy to move. The light emitting mode is more conducive to achieve a good welding effect. Support laser powers from 1kw to 1.5kw.

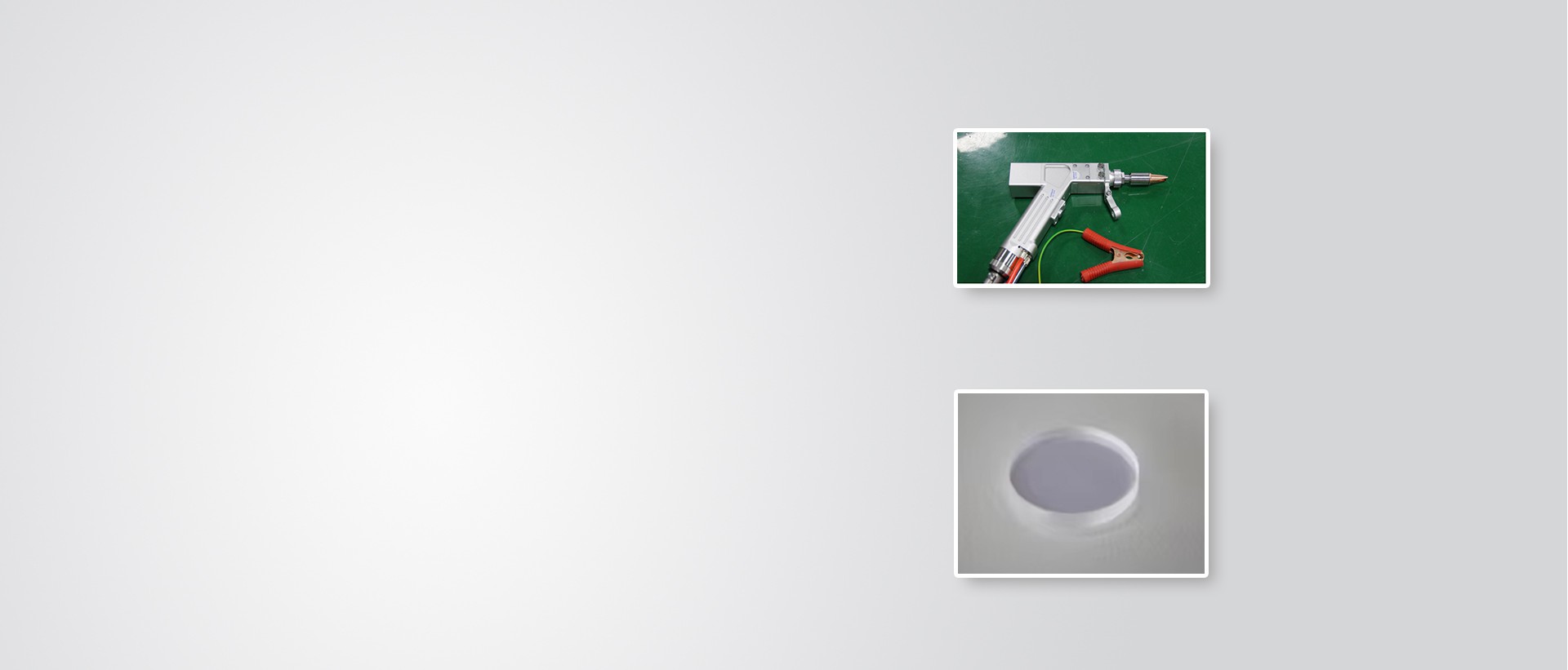

Laser Head

Equipped with lightweight welding head, can support multi-point temperature measurement real-time monitoring, dust resistance and anti-interference performance is excellent, work efficiency to a higher level, and efficient and convenient, focusing mirror,protection mirror drawer, easy to replace.

Control System

The newly developed control system, set a number of safety alarms, smaller volume, flexible operation, more stable, all parameters can be seen, welding quality is more perfect, deformation is small, high penetration, real-time monitoring of the state of the whole machine, avoid problems in advance.

Control Panel

Touch screen makes you change the parameters quickly when wearing gloves and easy to set up and operate. Multiple sets of parameter can be saved, and there is no need to adjust again for multiple welding times in the future after one test.

Control Panel

Touch screen makes you change the parameters quickly when wearing gloves and easy to set up and operate. Multiple sets of parameter can be saved, and there is no need to adjust again for multiple welding times in the future after one test.

Lens

There are Protective Lens, Focal Lens and Reflective Lens inside the Laser Head. Normally, Protective Lens are the wearing parts,when working after a long time, the user may need to change new lens to continue to work.

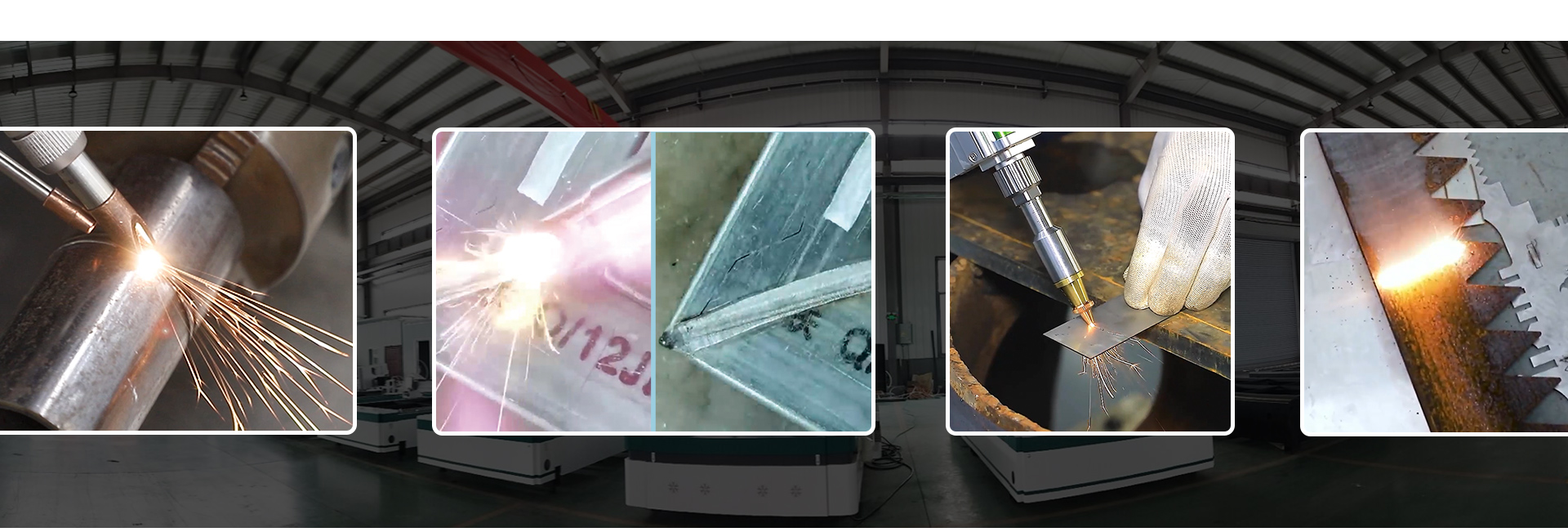

Application Industry

Kitchen and bathroom industry, advertising industry, door and window industry, mold industry, stainless steel products industry,handicraft industry, furniture industry, home appliance industry, auto parts industry, etc.

Conventional processing metal materials: stainless steel, carbon steel, copper, aluminum, alloys, etc

For any questions and inquiries, please contact with us freely!