As an important equipment in modern manufacturing industry, fiber laser cutting machine has been widely used in various industries due to its high efficiency, precision and environmental protection. This article will introduce the product features, application industry and working principle of fiber laser cutting machine in detail, in order to help readers better understand this advanced technology.

1. Product introduction

Equipment structure

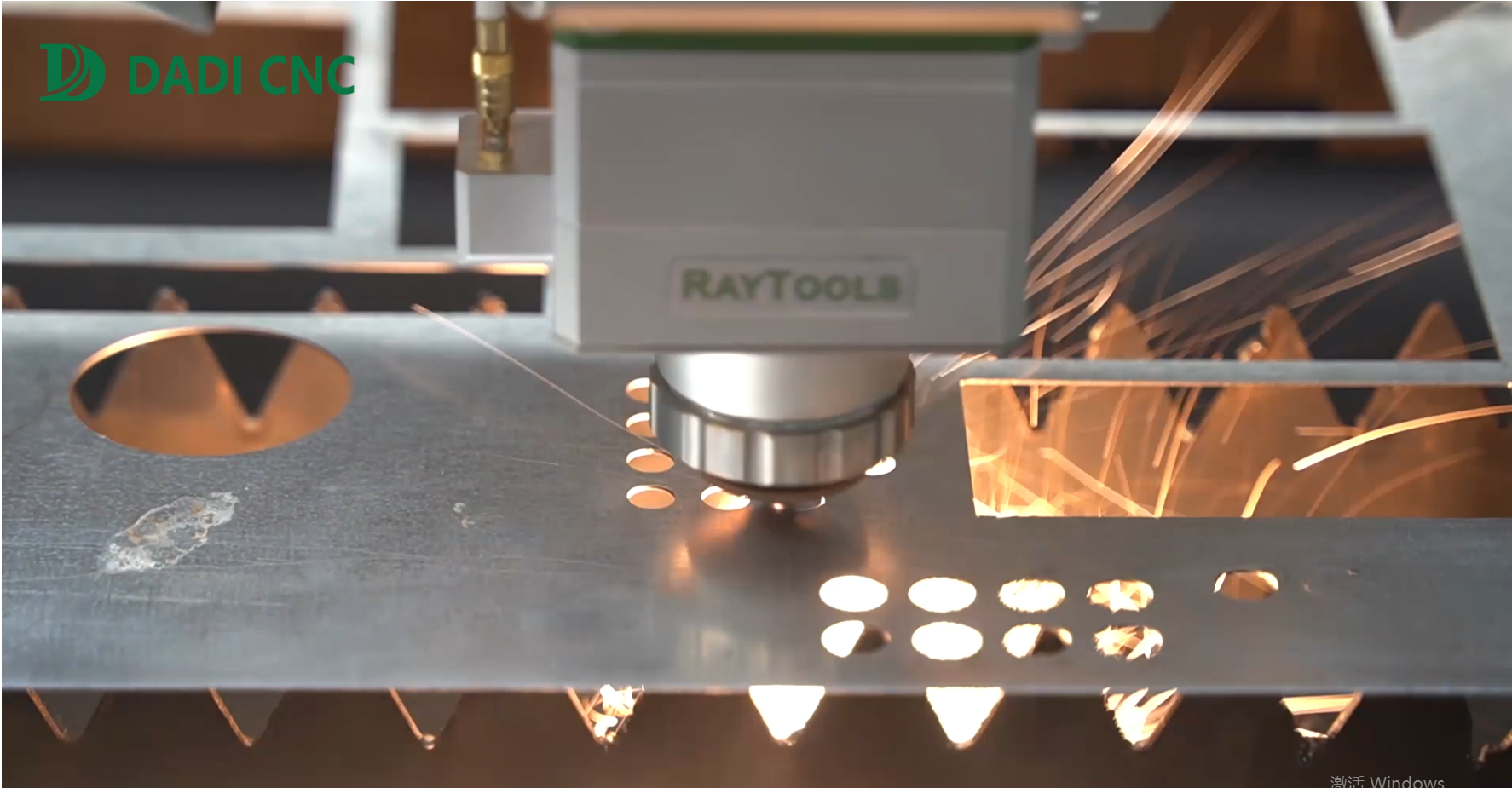

Fiber laser cutting machine is mainly composed of laser, cutting head, control system, transmission system and other parts. Among them, the laser is the core component, which is responsible for generating high-power laser beam; the cutting head is responsible for focusing the laser beam on the material to be cut; the control system is responsible for controlling the operation of the entire equipment; and the transmission system is responsible for feeding the material into the cutting area.

2. Equipment characteristics

Fiber laser cutting machine has the following characteristics:

(1) High precision: Fiber laser cutting machine adopts advanced control system and transmission system, which can achieve high-precision cutting and ensure the flatness and verticality of the cutting section.

(2) High efficiency: The cutting speed of fiber laser cutting machine is extremely fast, which can greatly improve production efficiency and reduce production costs.

(3) Environmental protection: Fiber laser cutting machines produce less exhaust gas and noise during operation, and have less impact on the environment.

(4) Easy to operate: The operation of fiber laser cutting machines is simple and convenient, and can be automated through the control system.

III. Application industry

Metal processing industry

Fiber laser cutting machines have been widely used in the metal processing industry. It can achieve fast and precise cutting of metal materials and is widely used in sheet metal processing, automobile manufacturing, aerospace and other fields.

IV. Detailed explanation of the principle

1. Working principle of laser

Fiber laser is the core component of fiber laser cutting machine. It uses rare earth elements such as erbium or ytterbium as activators to generate a high-power laser beam under light excitation. The laser beam has high beam quality and stability, which is a key factor in achieving high-quality cutting.

2. Working principle of cutting head

The cutting head of the fiber laser cutting machine uses high-precision optical elements and precision mechanical structures to focus the laser beam on the material to be cut. When the laser beam irradiates the surface of the material, the material is instantly heated and vaporized to achieve cutting. At the same time, the cutting head is also equipped with a water spray device to reduce the temperature of the material surface and prevent the material from burning.

3. Working principle of the control system

The control system of the fiber laser cutting machine adopts advanced computer technology and sensor technology to achieve precise control of the equipment. The control system can automatically adjust the output power of the laser and the motion trajectory of the cutting head according to the input cutting parameters (such as cutting speed, cutting depth, etc.) and the operating status of the equipment to ensure the flatness and verticality of the cutting section. At the same time, the control system also has fault diagnosis and alarm functions to ensure the safe operation of the equipment.

4. Working principle of the transmission system

The transmission system of the fiber laser cutting machine adopts advanced transmission technology and mechanical structure to achieve fast and stable transmission of materials. The transmission system can automatically adjust the transmission speed and position of the material according to the input cutting parameters and the operating status of the equipment to ensure the stability and accuracy of the material during the cutting process. At the same time, the transmission system also has an overload protection function to ensure the safe operation of the equipment.

V. Summary and Outlook

As an advanced manufacturing equipment, the fiber laser cutting machine has been widely used in various industries. It has brought revolutionary changes to the manufacturing industry with its high efficiency, precision and environmental protection. In the future, with the continuous advancement and innovation of technology, the performance of fiber laser cutting machines will be further improved, and the application field will continue to expand. Fiber laser cutting machines will become one of the important pillars in the manufacturing industry.