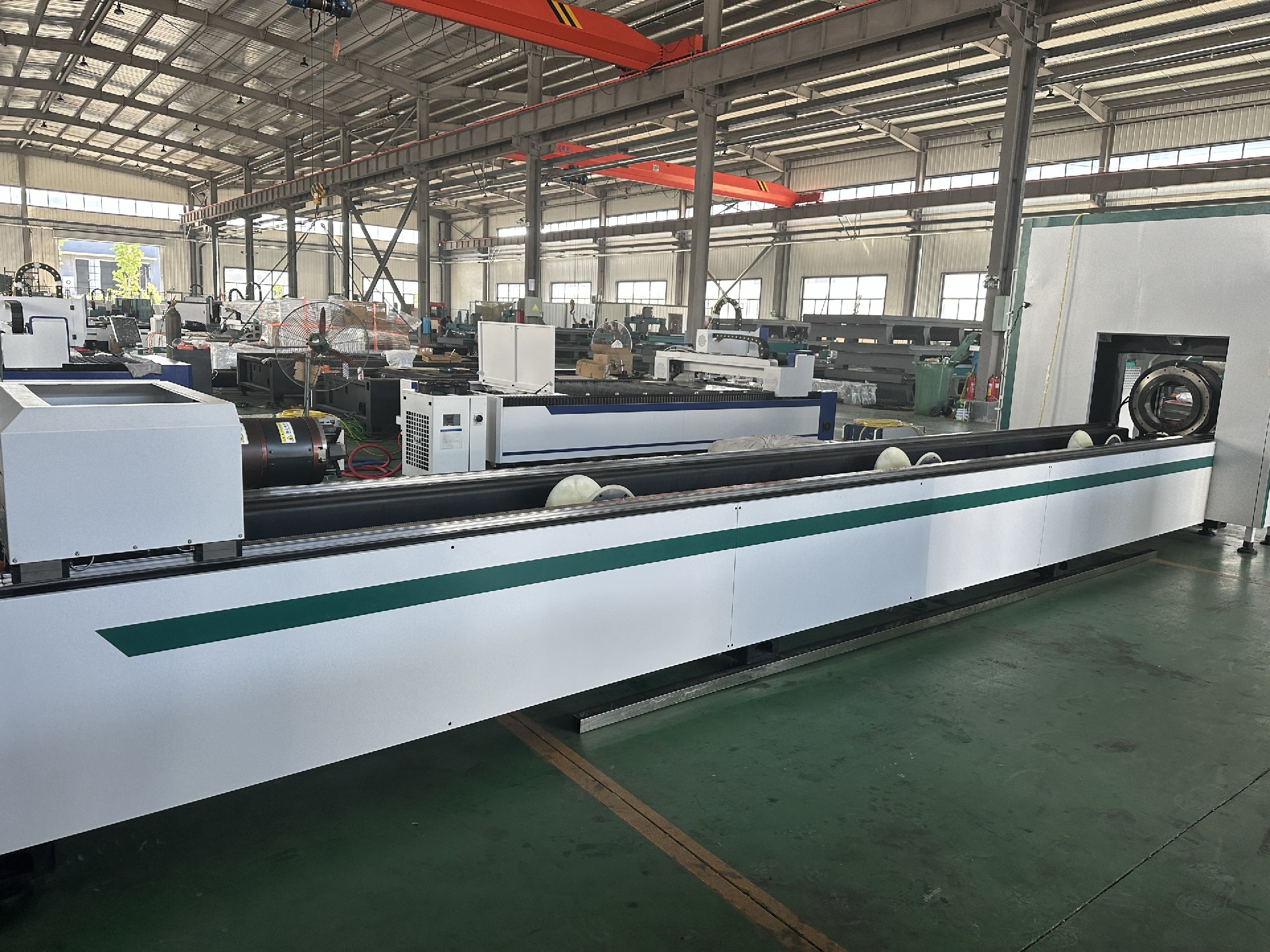

Laser cutting is a method that uses the high temperature generated by itself to melt or vaporize the surface of the material to achieve the purpose of cutting. Auxiliary gas is also used in the cutting process. The role of the auxiliary gas is to help increase the quality of the cutting and blow away the slag generated during the cutting process. Laser cutting has been widely used in the processing industry. This processing method is currently the most popular processing method in the processing industry. Laser cutting is so popular. Compared with other processing methods, does it have many advantages?

First, the processing mode is advanced and efficient. The extremely fine laser beam after focusing is like a tool. It can cut metal materials arbitrarily and finely without mechanical extrusion or mechanical stress, so it will not damage the shape of the processed object. The beam size after laser focusing is extremely fine, the heat-affected area is small, and it is not easy to deform. The cut seam is smooth and beautiful, no subsequent processing is required, and the processing is fine. Therefore, some processes that cannot be achieved by conventional methods can be completed.

Second, low cost, fully automatic, easy to operate 1. Fast laser processing speed 2. The "tool" used by the laser cutting machine is a focused light spot. No other equipment and materials need to be added. As long as the laser can work normally, it can be processed continuously for a long time. 3. Laser processing is automatically controlled by a computer, and no manual intervention is required during production.

Third, achieve zero backlog inventory. Laser processing is highly flexible and easy to change. For orders from different customers, you only need to draw a processing drawing on the computer, and the product can come out immediately, saving the conventional mold making fee, and effectively avoiding the differentiated production of the same product, reducing the risk of product backlog.

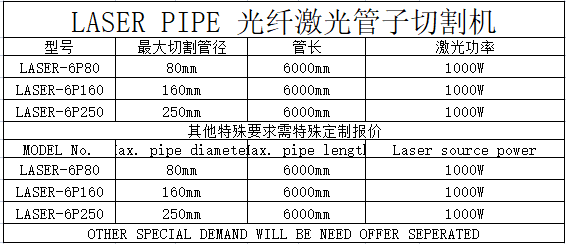

•Technical parametersTechnical parameters

•Display for Cutting sample drawing