As the "light sword" of modern metal processing, fiber laser cutting machines, with their high precision and efficiency, are widely used in industries such as sheet metal processing, automotive manufacturing, and mechanical equipment. However, when purchasing or using equipment, many users often face a core question: "My materials are primarily XX mm stainless steel or carbon steel. What power laser cutting machine should I choose?"

Choosing the right power maximizes efficiency and efficiency; choosing the wrong power can result in insufficient cutting capacity or significant waste of money and energy. This article will thoroughly explain the relationship between fiber laser cutting machine power and metal thickness.

I. Core Principle: The Relationship between Power and Thickness

Simply put, the power (W) of a laser cutting machine determines its "cutting force," while the thickness (mm) and type of material determine the required "force" to cut.

The higher the power, the greater the energy, the thicker the metal it can cut, and the faster the cutting speed. Lower power is more suitable for cutting thinner materials. Using thicker plates will result in poor cutting, slow speeds, and rough cross-sections.

This relationship isn't a simple linear relationship; it's influenced by a variety of factors, including the material's reflectivity, thermal conductivity, and cutting requirements (speed/quality). Below, we provide a detailed selection guide using the most common materials, including carbon steel, stainless steel, and aluminum, as examples.

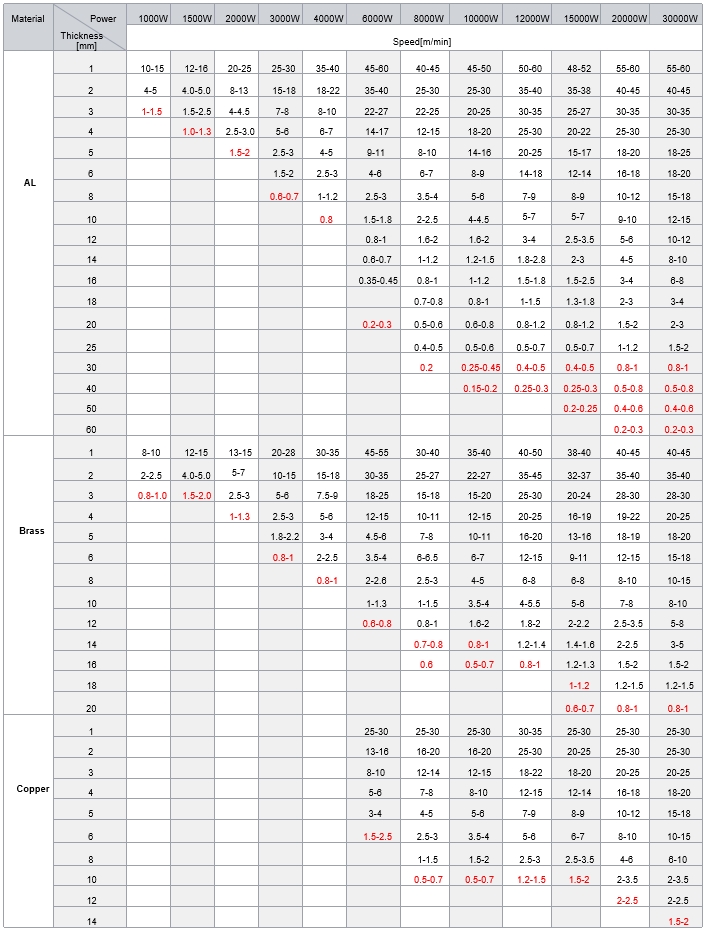

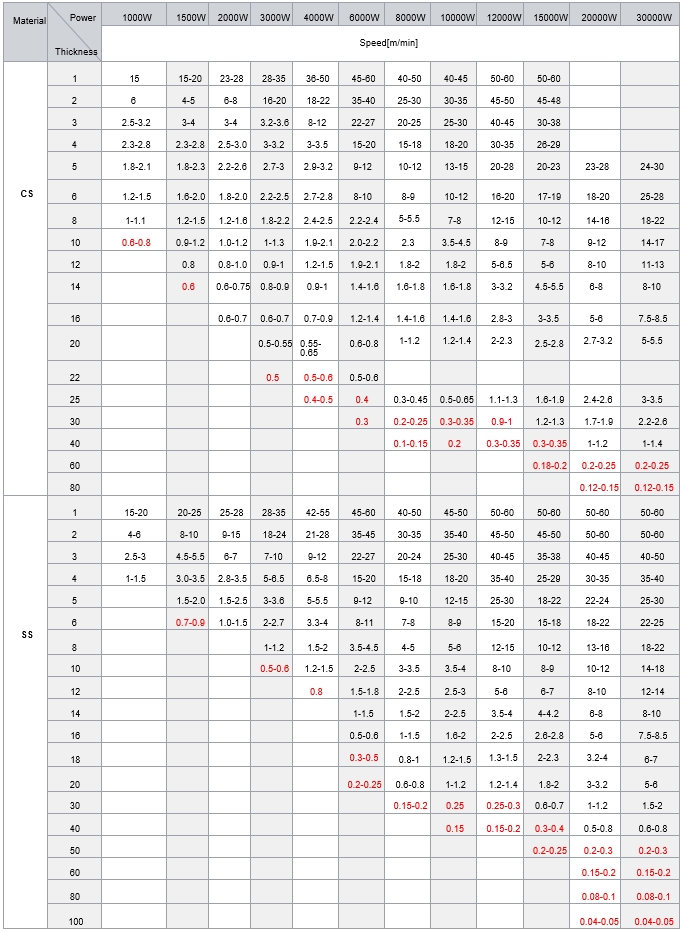

II. Capacity Comparison Table of Laser Cutters of Different Powers (Practical Guide)

The following is a general capacity table based on mainstream market equipment and actual processing experience, suitable for scenarios that require excellent cutting quality and efficiency.

Terminology:

Ideal Thickness: This refers to the thickness at which the machine can achieve high-speed, high-precision cutting, resulting in smooth, perpendicular cross-sections, minimal dross, and optimal quality and efficiency.

Extreme Thickness: This refers to the thickness at which the machine can achieve sufficient cutting speed, resulting in a smooth, perpendicular cross-section with minimal dross, optimal quality, and maximum efficiency.

Extreme Thickness: This refers to the thickness at which cutting is possible, but the cutting speed is very slow, resulting in a rough cross-section, severe dross, poor precision, and significant wear on the nozzle and lens. It is not recommended for routine processing.

III. In-Depth Analysis: Differences in Material Selection

Why are stainless steel and aluminum not as effective at cutting thicknesses as carbon steel at the same power? The reason lies in the physical properties of the materials.

1. Carbon Steel

Characteristics: Laser cutting of carbon steel primarily uses oxygen (O2) as the assist gas. During cutting, the laser heats the material to its ignition point, causing a violent oxidation reaction (combustion) with the oxygen. This reaction generates a large amount of heat, which, combined with the laser energy, "melts" and blows away the material. This is a "1+1>2" process, resulting in extremely high efficiency.

Power Selection Recommendation: Carbon steel offers the highest efficiency and best results for laser cutting. If you primarily process carbon steel thicknesses under 10mm, a 2000W-3000W laser cutter is the most cost-effective option.

2. Stainless Steel

Characteristics: Nitrogen (N2) is typically used as the assist gas for cutting stainless steel. The principle is to directly melt the material with a high-energy laser, then use high-pressure nitrogen to blow away the molten metal, preventing surface oxidation and maintaining its rust-resistant properties. This process relies almost entirely on the laser's own energy, thus requiring higher power.

Power Selection Recommendation: Cutting stainless steel of the same thickness requires approximately 1.5 to 2 times the power of carbon steel. For example, the ideal thickness for cutting stainless steel at 3000W is around 8mm.

3. Aluminum Alloy

Properties: Aluminum alloy has high reflectivity and high thermal conductivity. This means it reflects a significant amount of laser energy and dissipates it rapidly, resulting in low energy utilization. Therefore, a higher-power laser is required to overcome these characteristics for effective cutting. Nitrogen (N2) is also used as the assist gas.

Power Selection Recommendation: Cutting aluminum alloy requires higher power and places higher demands on the equipment (special lenses are required to prevent reflection damage). Even 6000W power is still quite challenging to cut aluminum alloys thicker than 10mm.

IV. Besides thickness and material, what other factors influence power selection?

1. Cutting Speed and Efficiency Requirements: If you pursue extreme productivity and want to cut thin sheets at high speeds, then choosing a higher power level is worthwhile. For example, a 3000W power source can cut 3mm thick carbon steel several times faster than a 1000W power source.

2. Cutting Quality Requirements: When cutting thin plate at high power, it's necessary to control heat input by adjusting parameters (such as reducing power or using high-frequency pulses) to avoid excessive burning while still achieving excellent quality. High-power equipment offers a quality advantage when cutting thick plate that lower-power equipment can't match.

3. Future Business Expansion: If you plan to process thicker and more diverse materials in the future, it's recommended to increase your power budget appropriately to create future redundancy and prevent equipment from becoming obsolete.

4. Budget Cost: Higher power levels increase both the equipment purchase price and ongoing electricity costs. A balance needs to be struck between investment cost and processing capacity.

V. Final Purchase Recommendations

For sheet metal processing of carbon steel ≤6mm: 1500W-2000W is the ideal, economical, and practical choice. For carbon steel ≤10mm, also suitable for stainless steel under 8mm: 3000W is the most mainstream and cost-effective "jack of all trades" model on the market.

For carbon steel ≥12mm or stainless steel ≥8mm: 6000W is recommended as a starting point. Higher wattage offers greater processing capacity and efficiency.

For non-ferrous metals such as aluminum alloys and copper alloys: 3000W is recommended as a starting point, with higher wattage options available depending on the thickness you primarily process.

Summary:

Choosing the wattage of a fiber laser cutting machine is like choosing engine displacement for a race car driver: "The more horsepower, the faster the road." The key is to consider the material types and thicknesses you most frequently process, while also considering production efficiency, processing quality, and future plans.

The best approach is to, after determining your budget, share your typical processing requirements (material samples, thickness, and expected output) with two or three reliable equipment suppliers. They should provide detailed trial cutting reports and plans, allowing you to compare and contrast your options and make the most informed decision.

I hope this popular science article can help you clear the fog and choose an invincible "light sword" for your business!