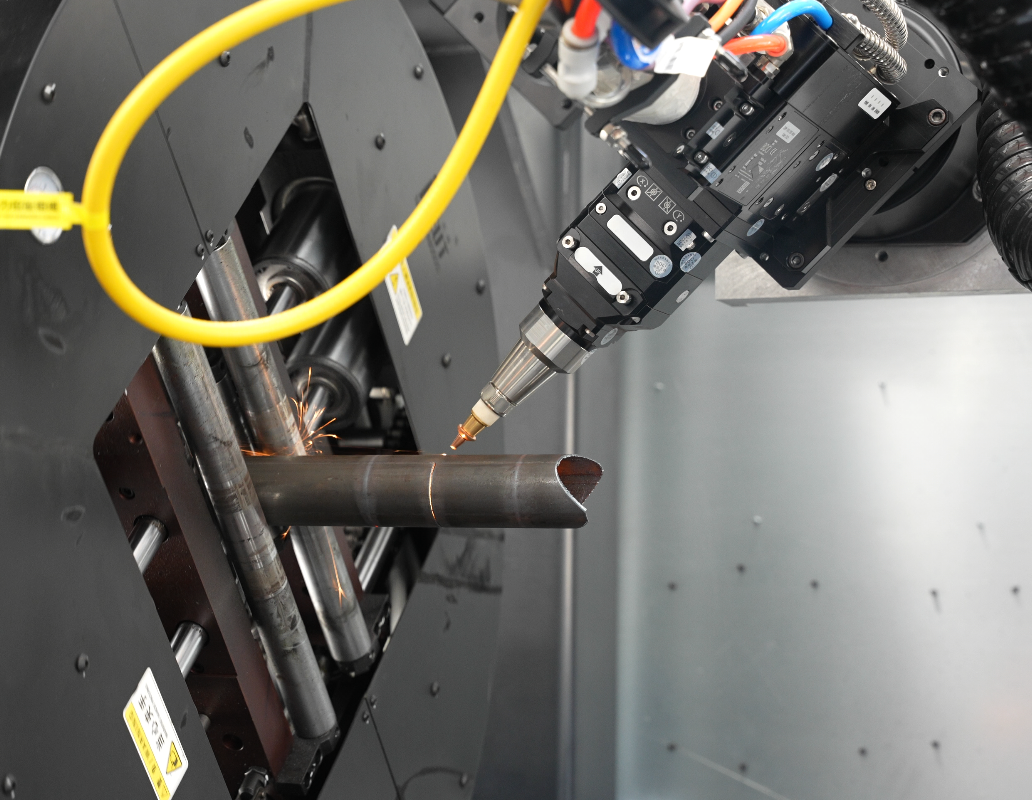

In the competitive world of industrial manufacturing, efficiency and precision are paramount. Fiber laser tube beveling machines offer a revolutionary solution, combining high-speed cutting with precision beveling capabilities in a single automated unit. This technology is redefining productivity standards in workshops and factories worldwide.

At DADI CNC, we design advanced laser systems integrated with cutting-edge features. This guide explores how this innovative technology can optimize your production line and deliver an excellent return on investment.

What is a fiber laser tube beveling machine?

A fiber laser tube beveling machine is a CNC system that seamlessly performs two key operations:

High-speed laser cutting: Utilizing a high-power fiber laser source, it cleanly cuts a wide variety of metal tubes (round, square, and rectangular).

Precision beveling: The cutting head dynamically tilts at a controlled angle (typically 45° ± 5°) to create precise, weldable edges.

This dual functionality eliminates the need for secondary operations, significantly reducing processing time and labor costs.

Key Benefits of Integrated Beveling Technology

1. Superior Weld Quality

Precise bevel edges ensure optimal weld fit, significantly enhancing joint penetration and structural integrity. This reduces weak points and increases product durability.

2. Superior Cost-Effectiveness

By combining cutting and beveling into a single step, manufacturers can save:

Reduce labor costs by reducing manual grinding

Reduce machine downtime by eliminating secondary operations

Reduce material waste through optimized nesting software

3. Enhanced Production Flexibility

Modern systems can process a wide range of materials, including:

Carbon steel, stainless steel, aluminum alloys, and brass

Manufacturers can quickly switch between jobs and pipe materials with minimal setup time.

Key Technical Considerations

When evaluating a system, prioritize the following features:

Laser power: 1500W-6000W+ available, depending on material thickness

Bevel range: At least ±45°

Positioning accuracy: ≤±0.1mm for consistent results

Automatic loading: Essential for high-volume production

CAM software: User-friendly interface with 3D simulation

Industry applications

This technology serves a wide range of industries:

Construction: Steel structural frames

Automotive: Exhaust systems and roll cages

Furniture: Decorative metal components

Energy: Pipe components and support structures

Why choose DADI CNC fiber laser tube cutting machines?

With over 10 years of industry experience, we offer:

Solutions tailored to your production needs

Comprehensive training and technical support

Global spare parts availability

24/7 remote maintenance service

Our equipment complies with international safety standards (CE, FDA) and comes with a comprehensive warranty.

FAQ

Q: What material thicknesses can these systems handle? A: Typically 0.5-15 mm, depending on laser power and material type.

Q: How does bevel accuracy affect weld quality?

A: Consistent bevel angles ensure uniform weld penetration, reducing defects and rework.

Q: Can existing pipe be processed?

A: Yes, with an adjustable collet system, it can accommodate a wide range of diameters.

Conclusion: The Future of Tube Manufacturing

Fiber laser bevel tube cutting machines represent the pinnacle of manufacturing efficiency. By integrating multiple processes into a single automated system, they deliver unprecedented precision while reducing operating costs.

https://www.dadilaser.com WhatsApp: +86 15688486209

Ready to boost your production capabilities? Contact our experts today for a personalized demonstration and quote. See how our technology can be your competitive advantage.